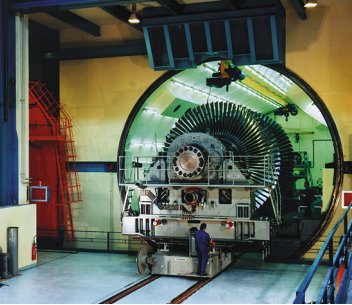

When you are dealing with rotors exposed to high centrifugal forces during operation, you have to be sure that they will not burst or deform permanently. This is normally done by performing strength tests at a speed above operating speed, or burst tests, or by recording Woehler curves. This will give you the reliability you need to operate your rotors.

Services offered by Schenck include spin-testing of your test specimens within the framework of the new or further development of your products or as part of quality control. Use Schenck's spin-testing rigs to better understand your rotors. They are ideally suited for research and development, and for small pilot batches or spot checks within the framework of production quality monitoring.

Read more

Aerospace, Aviation

Balancing machines for the aircraft and satellite engine industry: jet, prop and turbo prop

Aerospace

In aviation, the highest requirements are placed on installed components in terms of safety and reliability. This especially applies to instrumentations which are used in different places.

Load tests on airplane wings

In order to optimize the behavior of wings during a flight, the wings are already subjected to vibration tests during the construction. 120 wireSENSOR draw-wire sensors are connected to the wing and synchronized. In this way, any change of the wing form in the vertical direction can be tracked.

View product- Draw-wire displacement sensors for measuring ranges up to 50 m

Door lock detection

Before an aircraft starts, the doors are locked centrally. In order to determine the status of the locking, inductive displacement sensors from Micro-Epsilon are used. These detect the end position directly on the door lock.

View product- Inductive sensors (eddy current) for displacement, distance & position

Brake temperature measurement

Before an airplane can start, the temperature in the brakes must be below a certain limit. To determine the temperature, non-contact temperature sensors from Micro-Epsilon are used in the landing gear.

View product- Infrared pyrometers for universal measurements

Reliable position recognition of the Wing-Tip-Brake

The so-called Wing Tip Brake sits on the shaft in the outer wing area. It avoids uneven extension of slats and flaps and uncontrolled movements of the buoyancy aids by external influences. Inductive displacement sensors from Micro-Epsilon detect the position of the brake shoes.

View product-Inductive sensors (eddy current) for displacement, distance & position

Spin-Testing for Higher Safety

Spinning service

Spin Test Plants for Balancing and Testing The Mass Properties of Satellites

Small and large rotors as well as oscillating components are of paramount importance for the functioning of many products. They influence their safety, performance and quality. Even the smallest unbalance in these components in operation can have a dramatic effect – not only in the case of power-station turbines or vehicle components but also for small rotors like dental turbines.

Read more

Solutions for Structural and Functional Tests in Aerospace as well as Aircraft Electric System Testing

Test and Measurement Solutions for Aerospace Applications

The aviation and space industry has led the way in innovation for more than a century. Groundbreaking developments for military, commercial and business aircraft, spacecraft, rockets, satellites as well as unmanned aerial vehicles (UAVs) or advanced air mobility (AAM) are fascinating children and adults and revolutionizing mobility.

Read more

Electrodynamic LDS Shaker Systems

Electrodynamic LDS (Ling Dynamic Systems) Shakers delivering a force rating supporting a wide range of payloads. The LDS Shakers are well-suited for vibration testing products and structures from small components and hardware to very large devices and structures, such as satellite systems or airplane parts. Get in touch with our expert sales engineers to discuss your specific vibration testing needs or system requirements.

Read more

HighSpeed Data Acquisition in one solution

Genesis HighSpeed Transient Recorder & Data Acquisition System

Your modular platform for fast measurements of electrical and mechanical parameters. A transient recorder, data recorder and data acquisition system– all in one. Build your own configuration consisting of a mainframe, data acquisition input cards and the Perception software.

Your Genesis HighSpeed DAQ System consists of three components:

- A mainframe: The backbone of your system. It can a mainframe with integrated Windows PC with touchscreen. They are the right choise for portable or benchtop use in an instrument-like fashion Or you can choose to use a tethered mainframe which is supposed to be used stand-alone or with a PC connected via Ethernet. Perfect for fixed installations.

Note that you can also link multiple mainframes. - The input boards: Depending on your requirements, you can choose and combine the input boards for your application.

- The Perception software, which is designed for fast and reliable processing of large amount of data and is therefore ideal for high-speed data acquisition.

Need to use your own software? No problem, the Genesis HighSpeed hardware can be easily integrated into your own software.