Power & Energy

Monitoring of Compressors & Generators

Material Handling in Power Plants

DAQ, Durability & Efficiency Tests

Power & Energy

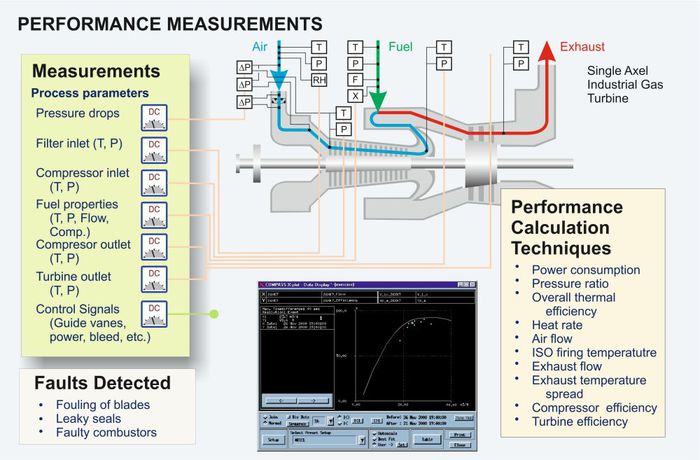

Machine Condition Monitoring in the Oil and Gas Industry

Monitoring strategies to address maintenance challenges.

The fiercely competitive environment in the oil and gas industries results in constant pressure on production facilities to be more flexible, efficient and productive. This puts greater demands on the machines, with their operation being driven to the edge of the operating envelope.

Read more

Innovative Solutions and Market Leading Technology for Fired Power Plants and Industrial Boilers

Safe, precision handling and feeding

Biomass-fired power plants require versatile solutions to overcome the challenges posed by diverse feedstock characteristics. With Schenck Process long-standing expertise in handling, conveying, weighing, and feeding bulk materials, they have the technology and know-how you need to get your fuels from trailer or container to boiler with maximum efficiency and minimum risk.

Read more

Measurement Solutions for the Energy Industry

HBM has developed its extensive range of equipment both for structural analysis and continued performance across all energy sectors including renewable energy, nuclear, oil and gas. This makes HBM the ideal partner for the energy industry whether working onshore or off for any application.

There are many fields of application in the energy industry where HBM measurement technology ensures reliable results- in energy generation as well as in power networks and the development of plants.

Read more

Under Difficult Electromagnetic Environmental Conditions, Get Clean and Reliable Measurement Results

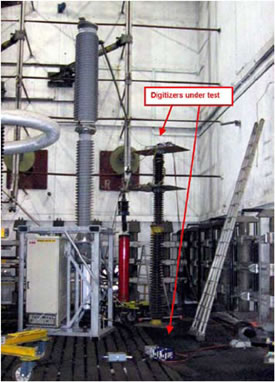

Grid Testing Solutions- High Voltage & Switchgear Testing

Grid testing solutions must contend with difficult electromagnetic and environmental conditions, providing clean and reliable measurement results to ensure a reliable supply of power from production through to consumers. Electrical power is- in most cases- not produced where it is consumed. The power grid covers the infrastructure connecting plants with end users, ultimately transporting electrical energy from where it is produced to where it is used.

The power grid is organized into different voltage levels from a few hundred volts (LV), to several 10 kV (MV) up to several 100 kV (HV), depending on the amount of power transportation capacity needed. Thus grid testing products must be capable of handling starkly different voltage levels.

The different voltage levels are interconnected by substations which contain voltage transformers, circuit breakers, surge arrestors, isolators etc. as well as other measurement equipment and switchgear.

Switchgear Testing

Switchgear testing is carried out to ensure reliability and safety of switchgear and circuit breakers. Typical switchgear tests are carried out against applicable standards. They must be carried out in both R&D facilities, for development purposes, as well as at independent test houses, for certification.

Read more

HV Impulse Testing

Most of the power grids worldwide are built by power lines on masts. They are highly exposed to lightning strikes with the risk of damage on the components in a substation, which poses a unique problem for grid testing. Damage to one or several of the elements may result in partial loss of the power distribution capability, unsatisfied consumers and high cost for repair. Performing Lightning Impulse testing on transformers, surge arrestors, isolators and switchgear is an important part of the quality proving process and documents the components withstand capabilities.

Read more

Current Zero Testing

Current zero (CZ) refers to the interruption phenomena in high power circuit-breakers. Many, if not all circuit-breakers in commercial use today are working based on contacts moving away from each other, thus creating an electrical arc between the contacts. The current zero phenomena is an indicator for the pressure, temperature, ion density, plasma flow, etc. Current zero measurements are used to understand the phenomena of the arc and to identify the dominant parameters for a successful interruption of the current. This shows the difficulties imposed on grid testing by complex electrical phenomena.

Read more

Battery Production

Energy storage devices such as lithium-ion batteries play a crucial role for the change in mobility and energy transition. In order to optimize the battery production, sensors are required which monitor the production line to the highest accuracy and dynamic. Micro-Epsilon offers reliable sensor technology from high precision distance sensors to infrared temperature measurement technology and 2D/3D profile sensors for multiple measurement tasks.

Read more

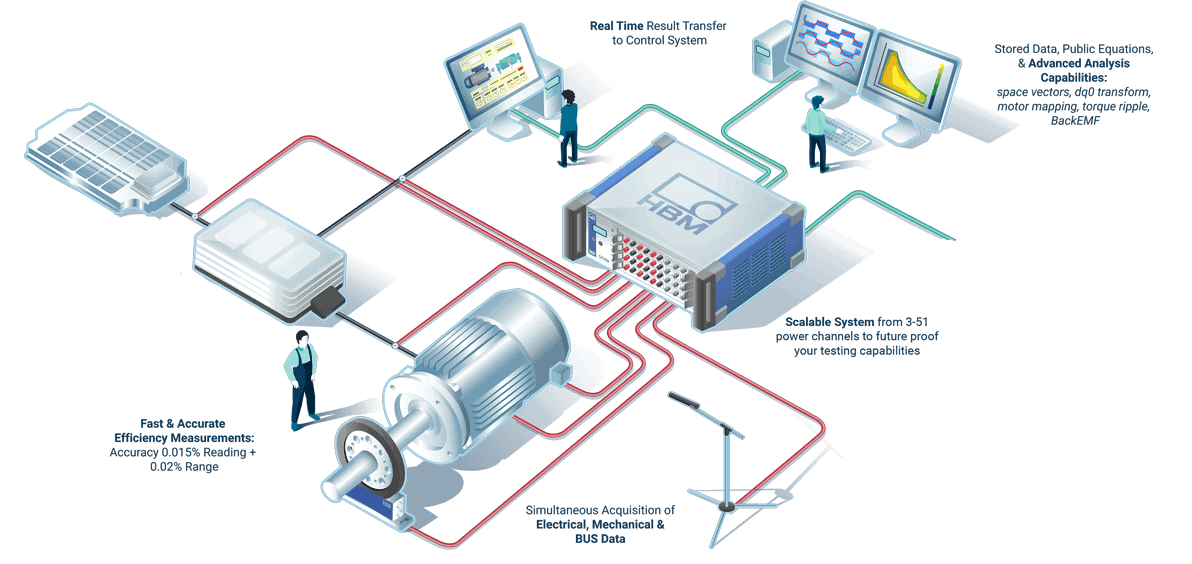

HBM Power Analyzers: Powerful Testing Solutions for Electric Drives

HBM eDrive series power analyzers are ideal testing solutions for inverter driven electrical machines. Based on digital cycle detection, the power analyzers offer unparalleled power computation, delivering reliable results even through dynamic load changes where conventional power meters would fail.

Unlike conventional power analyzers, which cannot cover all current electric drive technologies, eDrive power analyzers have enough flexibility, sample rates and extra features to cope with all modern drive technologies. They can be expanded with more channels, higher sample rates, and additional inputs to futureproof your eDrive testing solution.

- 3 to 51 power channels per mainframe

- Simultaneous acquisition of electrical, mechanical and bus data

- Real time result transfer to automation system and real time raw data storage

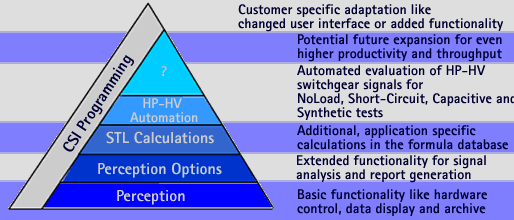

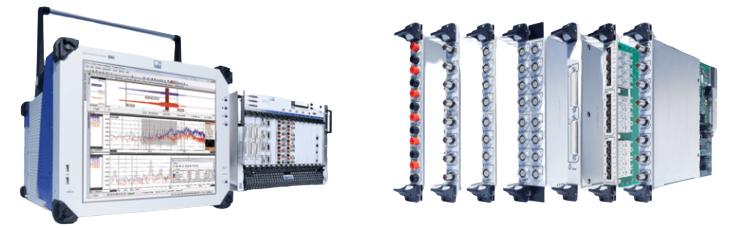

HighSpeed Data Acquisition In One Solution

Genesis HighSpeed Transient Recorder & Data Acquisition System

Your modular platform for fast measurements of electrical and mechanical parameters. A transient recorder, data recorder and data acquisition system– all in one. Build your own configuration consisting of a mainframe, data acquisition input cards and the Perception software.

Read more

Monitoring Techniques

LNG Solutions

Brüel & Kjær Vibro has 30 years of monitoring experience in the LNG industry. Today, their systems monitor nearly 20% of the world’s LNG production equalling 65 million tons per year of production from many happy customers worldwide. Brüel & Kjær Vibro successful long-term partnership with the LNG industry is based on state-of-the-art technology coupled with dedicated and passionate service specialists, who provide effective diagnostic and decision support whenever and wherever it’s needed.

Read more

Thermal Power

Monitoring high-speed machinery

Brüel & Kjær Vibro have extensive experience monitoring nuclear power stations, coal-fed steam turbines, gas turbine generators and combined cycle plants, for both the critical machines and the balance-of-plant. Many of the plants include machine protection systems, condition and performance monitoring.

Broad spectrum of application expertise

Depending on the plant and particular use, identical systems can actually have different monitoring requirements due to, for example, capacity requirements or the condition of the machinery. Brüel & Kjær Vibro incorporate this industry-specific experience when configuring the monitoring solution to the customer’s needs.

Reliability in any environment

Machines in conventional power plants operate in a demanding environment. Our monitoring solutions will ensure maximum uptime for your machinery.

Read more

Wind Power

Passionate about maximizing wind energy

As turbines age, the risk of machine failure increases. The expense of replacing a single component can be enormous (think of a gearbox), but add to that labor costs and a crane at a site that’s difficult to access.

Maintenance expenses can reach up to 20-25% of the total levelized cost per kWh produced over the lifetime of the wind turbine. This large expense is heavily influenced by the reliability and quality of operation and maintenance decisions that have to be made for these machines.

If you do not know the condition of your wind turbines, how can you avoid expensive failures and cost-effectively plan maintenance ahead of time?

Read more

Hydro Power

Solutions tailored to industry-specific monitoring needs

Hydropower plant operators have been relying on the effective monitoring solutions from Brüel & Kjær Vibro for decades. They monitor hundreds of hydroelectric machines under base and peak load, in reservoir, run-of-the-river and pumped storage power plants around the world.

Brüel & Kjær Vibro's solutions are based on decades of experience in vibration monitoring of rotating machinery. Their monitoring strategy includes several monitoring techniques, including air gap, magnetic flux and partial discharge measurements. They are your one-stop shop for efficient and reliable condition monitoring of hydroelectric power plants.

Read more