Displacement,Color & IR Temperature Sensors & Systems

High Precision Sensors, Measurement Devices and Systems

from Micro-Epsilon

Micro-Epsilon offers the largest range of high precision displacement sensors, infrared temperature sensors, color sensors as well as dimensional measurement devices and systems for industrial applications.

Whether your field is research and development, manufacturing automation or machine building, we offer solutions that meet the specific requirements of your individual measurement task.

More than 30,000 users worldwide rely on Micro-Epsilon – so let us convince you too!

Sensors for Displacement, Distance & Position

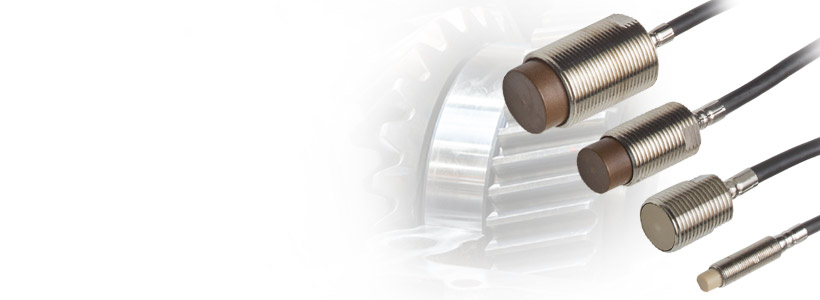

Eddy Current Sensors

Inductive sensors from Micro-Epsilon are based on the eddy current principle and designed for non-contact measurement of displacement, distance, position, oscillation and vibrations. They are particularly suitable when high precision is required in harsh industrial environments (pressure, dirt, temperature). Inductive sensors from Micro-Epsilon offer extremely precise measurements where sub-micron accuracy is required.

Read more

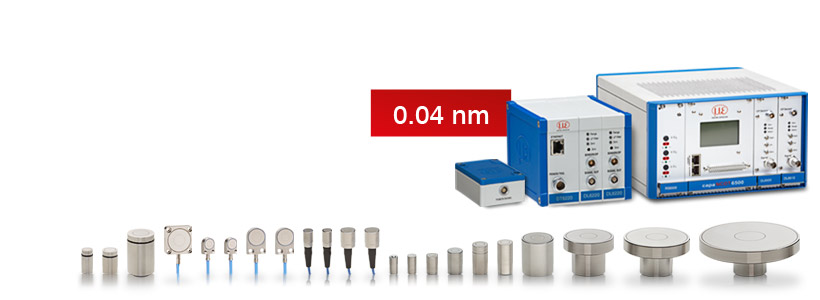

Capacitive Sensors

Capacitive sensors are designed for non-contact measurement of displacement, distance and position, as well as for thickness measurement. Due to their high signal stability and resolution, capacitive displacement sensors are applied in laboratories and industrial measurement tasks. In production control, for example, capacitive sensors measure film thickness and application of the adhesive. Installed in machines, they monitor displacement and tool positions.

Read more

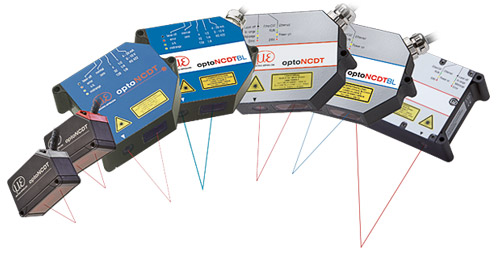

Laser Sensors

optoNCDT sensors have set milestones for industrial laser displacement measurement. Whether for displacement, distance or thickness measurement, Micro-Epsilon laser sensors are considered one of the best in their class. These laser sensors are used e.g. in measurement and monitoring tasks in factory automation, electronics production, robotics and vehicle construction.

Read more

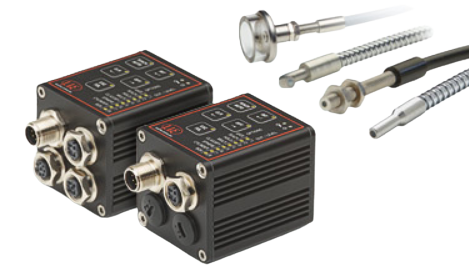

Confocal Sensors

The confocal chromatic confocalDT measuring system is used for fast distance and thickness measurement. Different sensor models and controller interfaces open versatile fields of application, e.g. in the semiconductor industry, glass industry, medical engineering and plastics production.

Read more

Laser Distance Sensors

Laser distance sensors are designed for non-contact distance measurements: laser gages for measuring ranges up to 10m, laser distance sensors for up to 3,000m. These sensors are used for positioning and type classification in machine building and handling equipment.

Read more

Inductive Sensors (LVDT)

Micro-Epsilon offers a large range of inductive sensors for displacement and position measurement from conventional LVDT sensors and inductive sensors with integrated controller to customer-specific high-volume versions. The induSENSOR displacement sensors from Micro-Epsilon are used in automated processes, quality assurance, test rigs, hydraulics, pneumatic cylinders and automotive engineering.

Read more

Magneto-Inductive Sensors

mainSENSOR is based on an innovative measuring principle, which has been developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors. Magneto-inductive sensors are frequently used as alternative to inductive sensors and proximity sensors in process automation, the packaging industry and in machine monitoring. Measuring the distance to a magnet which is fixed at the measurement object, the sensor outputs a continuous, linear signal. As different strength magnets are applied, measuring ranges of between 20 mm and 55 mm can be achieved. However, in order to adapt the measuring range, it is only necessary to change the magnet.

Read more

Draw-Wire Sensors

Draw-wire sensors of the wireSENSOR series measure almost linearly across the entire measuring range and are used for distance and position measurements of 50mm up to 50,000mm. Draw-wire sensors from Micro-Epsilon are ideal for integration and subsequent assembly in high volume OEM applications, e.g. in medical devices, lifts, conveyors and automotive engineering.

Draw-wire sensors of the wireSENSOR series measure almost linearly across the entire measuring range and are used for distance and position measurements of 50mm up to 50,000mm. Draw-wire sensors from Micro-Epsilon are ideal for integration and subsequent assembly in high volume OEM applications, e.g. in medical devices, lifts, conveyors and automotive engineering.

Read more

IR Temperature Sensors

thermoIMAGER TIM

TIM thermal imaging cameras are designed for non-contact measurement of surface temperatures from -20 °C to 1900 °C. They enable efficient monitoring and control of temperature-critical processes both with low temperatures (e.g. in cooling chains) and with very high temperatures (e.g. in glass and metal processing). Their high thermal sensitivity makes these infrared cameras ideally suitable for precise and dynamic tasks. Different performance classes enable a suitable model to be selected for every application. The camera is connected via a USB interface, which also supplies the power.

Read more

thermoMETER CT

Infrared pyrometers of the thermoMETER CT series can be used in a wide variety of applications. From low temperatures prevalent in cooling chains or laboratories, to the highest temperatures in hot molten metals and blast furnaces - these IR pyrometers measure precisely and reliably.

Read more

thermoMETER CT Laser

thermoMETER CTLaser pyrometers are used for both industrial measurements and Research and Development. Two laser beams mark the measurement spot which ensures precise temperature measurements. The smallest measurement spot is 0.5 mm. The thermoMETER CTLaser infrared pyrometers can be used with various measuring objects. From extremely low temperatures (-50°C) to the highest temperatures (975°C), these IR pyrometers measure precisely and reliably.

Read more

thermoMETER CS

The infrared thermoMETER CS temperature sensors are equipped with a miniature sensor that is particularly suitable for installation in confined spaces. The small size and temperature resistance up to 120°C open up a wide range of applications.

The infrared temperature sensors are available in different versions, e.g., with laser aiming or as a two-wire version for easy integration.

Read more

Color Sensors

Color sensor systems for material, surface, turbidity and gloss

The colorSENSOR CFO is a new controller for precise color recognition in industrial measurement tasks. The CFO series is distinguished by high color accuracy, state-of-the-art interfaces and intuitive operation. The controller is connected to CFS sensors with integrated optical fibers, which can be adapted for different measurement tasks. The colorSENSOR CFO is used in color recognition tasks on interior parts such as head supports, in packaging control or in color sorting tasks with crown caps, closures or labels.

Read more

High Speed Photospectrometer colorCONTROL ACS7000

The colorCONTROL ACS7000 color measurement system not only recognizes reference colors by comparison, but identifies individual colors clearly from their coordinates in the color space. With its high speed spectrometer, the colorCONTROL ACS7000 is suitable for applications where colors and shades have to be examined online with the highest accuracy.

Read more

Sensor systems for LED color and intensity tests

The colorCONTROL MFA is used for flexible color inspections and intensity testing of LEDs, displays and colored objects. The flexible positioning of the sensors in relation to the objects, as well as their high repeatability, measuring rates and dynamics are particularly favorable. One colorCONTROL MFA monitors up to 28 test objects simultaneously.

Read more

Robust fiber optic CFS sensors for industrial applications

Operating the optoCONTROL CLS1000 controllers requires sensors that are used on the measuring point. Depending on the measurement task, the sensors can be individually combined. The high-quality sensors with fiber optics are characterized by small installation dimensions and robust materials. This makes them particularly suitable for mechanical stress and harsh ambient conditions such as high temperatures. The sensor can also be used in restricted areas as the sensor head requires a minimum of installation space.

Read more

2D/3D Measurement

3D Sensors for Geomerty and Surface Inspections

The new generation of Micro-Epsilon’s 3D sensors impresses with high accuracy during measurement and assessment of components and surfaces. The surfaceCONTROL and reflectCONTROL inspection systems from Micro-Epsilon are intended for matt and shiny surfaces respectively. The 3D snapshots are recorded in a short time and provide detailed 3D point clouds.

These 3D sensors are used, e.g., for geometric component testing, position determination, presence checks and the measurement of flatness or planarity. Thanks to their high performance, the sensors are used for inline applications, on robots and also for offline inspection.

Read more

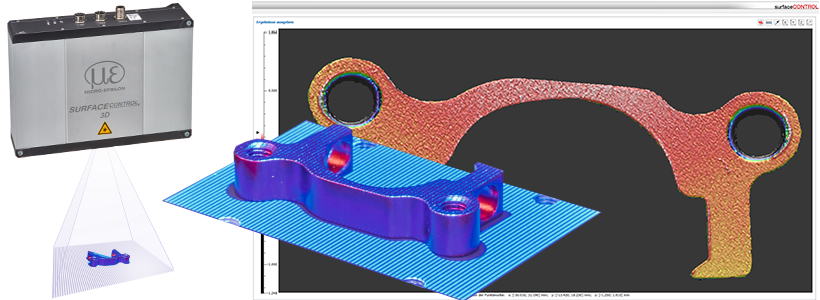

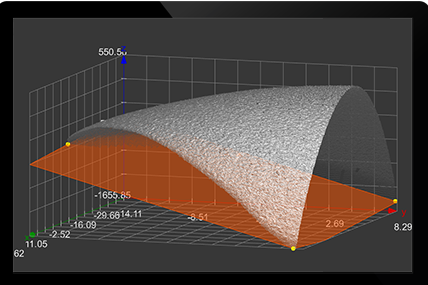

surfaceCONTROL - 3D Snapshot Sensor

surfaceCONTROL sensors are used for 3D measurements and surface inspections. The sensors use the fringe projection principle to detect diffuse reflecting surface and to generate a 3D point cloud. This point cloud is subsequently evaluated in order to recognize geometry, extremely small defects and discontinuities on the surface. Sensors with different measurement areas are available. This enables the inspection of the finest of structures on components as well as form deviations on large-area attachments. Powerful software packages are available for evaluation and parameter setting.

Read more

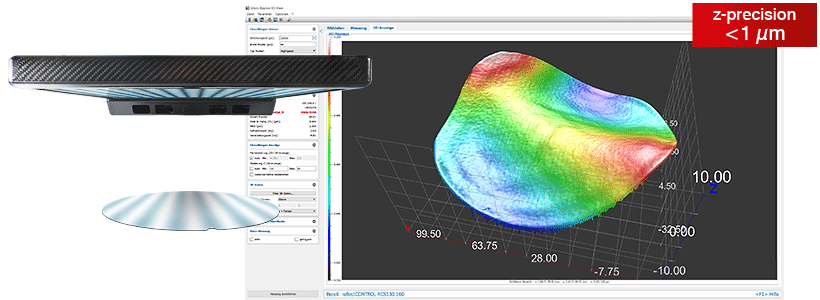

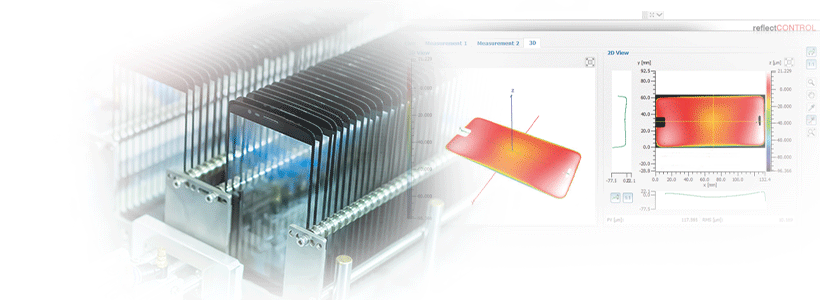

reflectCONTROL for shiny surfaces

Deflectometry sensor for 3D measurements of shiny surfaces

The reflectCONTROL RC130 is intended for shape measurements of shiny objects. This sensor displays a striped pattern which is mirrored by the surface of the measuring object into the sensor cameras. The sensor provides a 3D image of the surface which allows for the topology of the components (e.g. flatness, deflection, curvature) to be determined. The RCS130 model is specially optimized for measurement and inspection tasks, e.g., in production lines. Moreover, the sensor has a GigE Vision interface that offers GenICam compliant data.

Read more

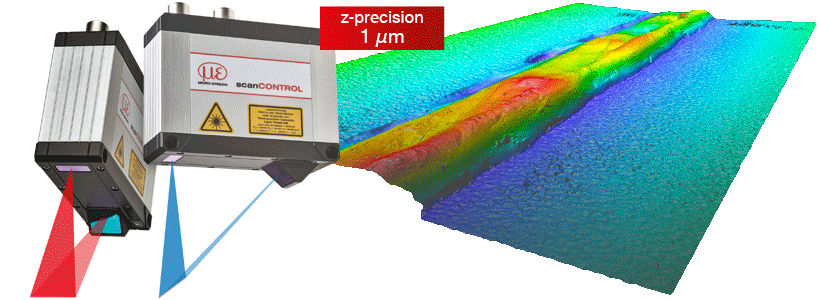

scanCONTROL 3D laser scanners

scanCONTROL 3D scanners are used for precise inline 3D measurements in numerous applications. Scans are performed by moving the scanner or the target. Due to their low weight, the scanners are ideally suited both for robotic applications and inline production monitoring. These 3D laser scanners are characterized by high dynamics, absolute precision and their compact size. With the scanCONTROL 3000 and the new scanCONTROL 3002 series, Micro-Epsilon offers a comprehensive portfolio with numerous measurement areas, Red and Blue laser technologies and extensive accessories.

Read more

3DInspect software

3DInspect is a uniform and user-friendly software tool for all 3D sensors from Micro-Epsilon. Parameter setting of the 3D sensors and recording of the measurement data are done directly in the 3DInspect software. Powerful tools allow point cloud alignment and filtering, intuitive detection and selection of relevant areas, and program combination. The 3D point clouds can be processed as required and measured values can be output to the controller.

Read more

Software integration

3D sensors from Micro-Epsilon are equipped with an easy-to-integrate SDK (Software Development Kit). The SDK is based on the GigE Vision and GenICam industry standards including the following function blocks:

- Network configuration and sensor connection

- Extensive sensor control

- Transmission control of measurement images

- Management of user-defined parameter sets

- C++ sample programs and documentation

Access to the sensor via GigE Vision is also possible without SDK using a GenICam client.

Read more

Industrial Performance Unit

The Industrial Performance Unit is a powerful computing platform for the efficient commissioning of Micro-Epsilon 3D sensors. The fully compatible controller is ideally suited to inline processes in 3D measurement tasks. The intuitive 3DInspect software with Valid3D technology enables simple and fast sensor parameter setting, which allows measurements to start immediately. The Industrial Performance Unit directly processes three-dimensional data, which is subsequently evaluated and assessed via the 3DInspect software. Results can be output via the integrated PROFINET and EtherNet/IP interfaces.

Read more

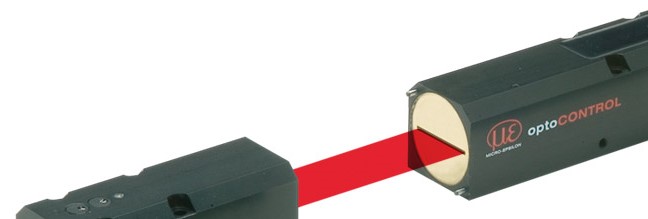

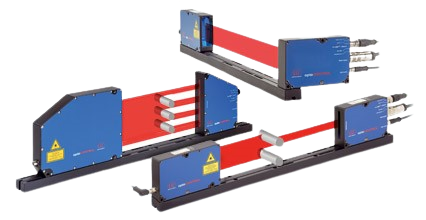

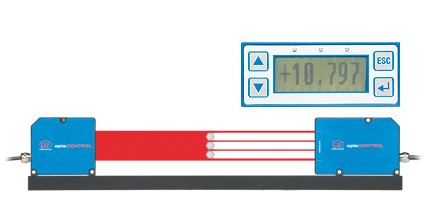

Optical precision micrometer with high resolution

Optical micrometers from Micro-Epsilon operate according to the transmitted light principle (ThruBeam micrometer). Here, the transmitter produces a parallel light curtain that is transmitted via a lens arrangement into the receiver unit. The beam is interrupted if an object is in the light path. The resulting shadowing is detected by the receiving optics and output as measurement value. Most optical micrometers are used for dimensional measurements in production, machine monitoring and quality assurance. Parameters such as diameter, gap, height and position are detected with high accuracy.

Read more

optoCONTROL 1200

The optoCONTROL 1200 is based on the principle of light quantity measurement. The compact laser micrometer has all the evaluation electronics integrated in the case and the mounting is very flexible. High dynamic applications can be measured due to the measuring rate of 100 kHz.

Read more

optoCONTROL 2520

The optoCONTROL 2520 is a compact laser micrometer with integrated controller. A high resolution, model variant with measuring ranges of 46 mm and 95 mm as well as variable mounting distances allow a wide range of applications in quality monitoring and production control. The measurement object can be placed at any position within the light curtain and the distance from transmitter to receiver can be freely selected.

Read more

optoCONTROL 2600

optoCONTROL 2600 is a LED based micrometer with an integral high resolution CCD camera for geometrical measurements. LED technology and the lack of mechanical components provide an extremely long service life.

Read more

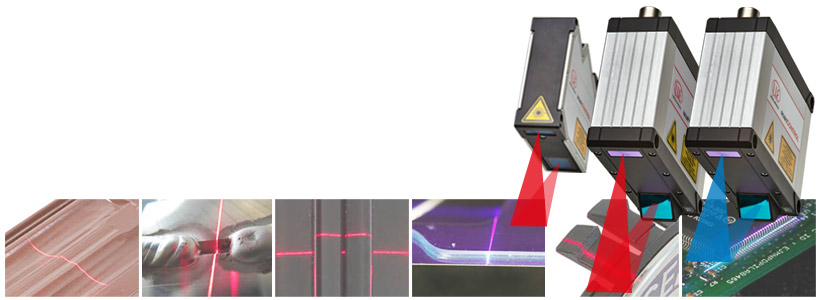

Laser scanners for 2D/3D profile measurements

Laser scanners from Micro-Epsilon are among the highest performing profile sensors in the world with respect to accuracy and measuring rate. They detect, measure and evaluate profiles on different object surfaces without contact. The available models are suitable for numerous industrial applications. The integrated intelligence in their sensor head (scanCONTROL SMART) solves versatile measurement tasks. Models for the customer’s own programming are available for integrators. The scanCONTROL profile scanners do not require any external controller.

Read more

Configure your laser profile scanner

scanCONTROL 25x0

scanCONTROL 25x0 laser scanners are designed for industrial measurement tasks. The combination of compact design, versatility and signal stability creates an excellent price/performance ratio, especially for measurement tasks involving large quantities. The scanCONTROL 25x0 laser scanners are available with three measuring ranges with either red or blue laser. Optional accessories, different cable types and interface modules enable a wide range of applications in the production line and in machine building.

Read more

scanCONTROL 29x0

The scanCONTROL 29x0 series is focused on compact size and low weight. The controller is integrated in the housing, simplifying cabling arrangements and mechanical integration. Due to its compact design and high profile resolution, this series is especially suitable for static, dynamic and robotic applications that require highest precision.

Read more

scanCONTROL 30x2

scanCONTROL 30x2 laser scanners are powerful profile sensors in terms of size, accuracy and measuring rate. These laser scanners provide calibrated 2D profile data with up to 5.12 million points per second. With a maximum profile frequency of 5 kHz, the scanners are designed for precise profile measurements in dynamic processes. The sensor matrix offers a resolution of 1,024 points with a point distance from 24 µm. This means that even small details can be detected reliably.

Read more

scanCONTROL 30x0

scanCONTROL 30x0 laser scanners are among the highest performing profile sensors in terms of their size, accuracy and measuring rate. They provide calibrated 2D profile data with up to 7.37 million points per second. Their profile frequency of max. 10 kHz enables precise profile measurements in dynamic processes. The high-resolution sensor matrix offers a resolution of 2,048 points with an ultimate point distance of just 12 µm. This is how even the finest of details can be detected reliably.

Read more

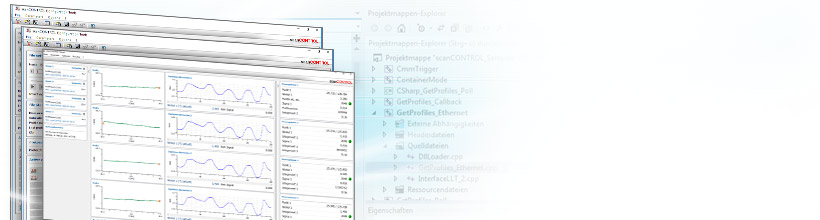

Software

For these laser profile scanners, special sensor configuration, data display and output applications are available. The software is available free of charge for each product series.

Read more

Options & Accessories

The scanCONTROL sensors can be used directly due to free software. In order to extend the functionality of the laser scanners, a comprehensive range of optional accessories is available.

Read more

Applications for 2D/3D laser scanners

Select applications by:

- Material

- Measurement

- Industry

Inspection Systems for the Metallurgical Industry

Measuring and Inspection Systems for the Metallurgical Industry

For the steel and aluminum industry, Micro-Epsilon offers innovative measuring and inspection systems for thickness, profile and surface measurements. Performance and quality, as well as reliability of products and services have made Micro-Epsilon one of the leading suppliers of inspection systems for optical thickness measurement used in the metals industry.

Micro-Epsilon's non-contact thickness measuring systems are used wherever high-precision thickness monitoring is required for control and quality assurance. Both in hot rolling mills, in continuous casting plants and in cold rolling mills and service centers, the Micro-Epsilon measuring systems operate reliably and with maximum precision. Numerous, successful installations in 13 countries around the world in milling lines and processing lines speak for themselves.

Read more

Thickness Measurement

Aluminum Plate Thickness - Non-contact measurement of thickness and width in hot and cold rolling mills (thickness 10 - 50 mm)

The demand for aluminum is constantly increasing due to its special technical properties. It can be made thinner and thinner as the strength increases. This is accompanied by tight manufacturing tolerances, which require measurement technology with more precision.

Read more

Welding Automation

Automated welding processes make welding operations faster and more repeatable. The top priority here is maximum productivity along with consistent quality. In modern spot welding, additive welding processes and robot welding, all process steps are clocked and carried out with the highest precision. In this respect, high precision sensors from Micro-Epsilon impress in numerous measurement tasks and are used, e.g., for control, intensity control and weld path planning.

Read more

Inspection

Non-contact inspection of extruder bores

The idiamCONTROL sensor system precisely measures the inner diameter of bore holes such as in extruders in order to determine the wear. The idiamCONTROL is guided into the bore hole and determines the bore hole diameter while being pulled out. Wear-based tolerance violations are automatically displayed and can be output via USB.

Read more

Measuring and Inspection Systems for Rubber and Tires Industry

Tire Industry

Tire geometry inspection

Monitoring tire geometry i.e. the measurement of radial or lateral unbalance as well as side wall detection for bulges, constrictions, dents etc.at the end of the production process. The TGI 8302.LLT system can be easily integrated while offering precise measuring results.

Read more

Profile measurement of inner liner material

During the production of inner liner, the thickness profile of inner liner material is measured immediately after the calender using systems of the thicknessCONTROL TIP series. Accurate precision of the non- contact optical system ensures high quality and security of the product produced. Sensors belonging to the thicknessCONTROL RTP series can also be applied for this application.

Read more

Profile measurement of treads

The profilometer of the thicknessCONTROL.TTP series accurately measures the thickness profile of tire tread or side walls during the extrusion process and enable therefore an efficient control during production as well as a fully recorded quality control.

Read more

Offline profile thickness measurement

The profilometer thicknessCONTROL TTP 8302.T is applied for sampling regarding the extrusion process of treads, side wall and inner liner material. The system offers measuring results in high precision and allows therefore an efficient production as well as a fully recorded quality control.

Read more

Length measurement of tread strips

For tire production, tread strips are cut from the extruded strip material. The system TLS 8303.I is applied in the extrusion line to measure the length of the strips immediately after the cutting machine in order to ensure a secure production process in high quality.

Read more

Inspection of color codes on treads

The system TCC 8303.I marks the running surface which is output after the extruder, inspects the color lines for their completeness and measures the width of the running strip.

Read more

Other sections of the rubber processing industry

Profile thickness measurement of roller head installations

For the production of reeled resistors or sheet goods on roller head installations the thickness measurement is an essential factor for controlling and monitoring the production process. Applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Read more

Thickness measurement of calenders

For the production of reeled resistors or sheet goods in calenders the thickness measurement is a vital factor for controlling and monitoring the production process. By applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Read more

Measuring and Inspection Systems for Plastics

Thickness profile of blown films

Material parameter:

- Thickness up to 300µm (reversing) and 500µm (traversing), non conductive material

- Width from 255mm to 3600mm (double flat)

- Bubble vibration (horizontal) up to 10Hz (non-contact sensor, reversing - BTS 8101NC)

- Different sensor coatings allow measurements on different film types

Read more

Thickness measurement of flat film

Material parameter:

- Film thickness 30µm up to 6mm

- Film width up to 3000mm

- Material feed up to 300m/min

Read more

Thickness of thermoformed flat film

Material parameter:

- Film thickness 0.1mm up to 6mm

- Film width up to 3000mm

- Material feed up to 14m/min

Read more

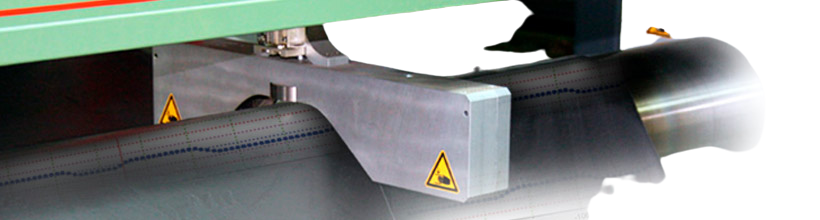

Thickness measurement in hot melt calenders

Material parameter:

- Film thickness 30µm up to 6mm

- Film width up to 3000mm

- Material feed up to 14m/mi

Read more