Strain Gauges & Accessories

Our range of strain gauges comprises of an extensive assortment for the most widely differing strain measurement applications – from experimental stress ... analysis, durability testing, transducer manufacturing

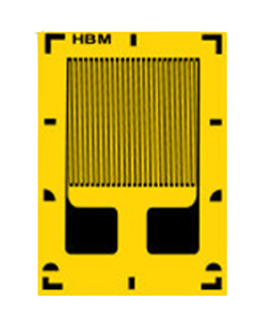

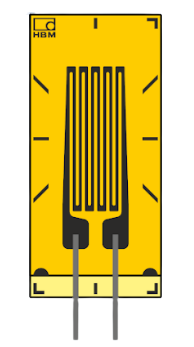

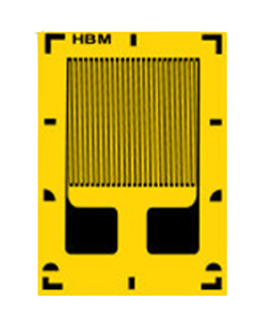

Y Series Universal Strain Gauges: Over 2,000 Different Types Available

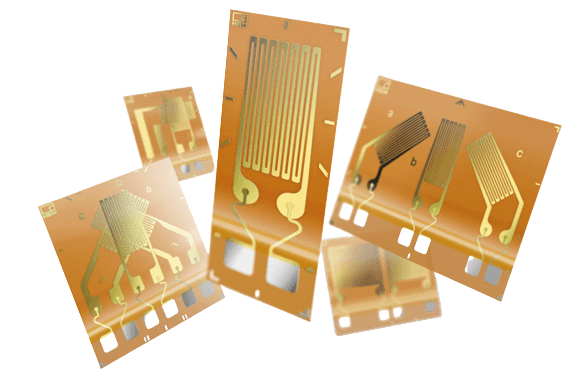

Y series foil strain gauges (SG) can be used in many areas, for static or dynamic stress analysis. They measure highly precisely, are robust, extremely flexible and can be installed on different materials due to seven different types of temperature response matching. Y series universal SG are available in many versions for a wide range of applications - thanks to properties such as geometry, nominal (rated) resistance and measuring grid length that can be combined as required. Over 260 frequently used types (“preferential strain gauge”) are immediately available immediately from stock.

Read more

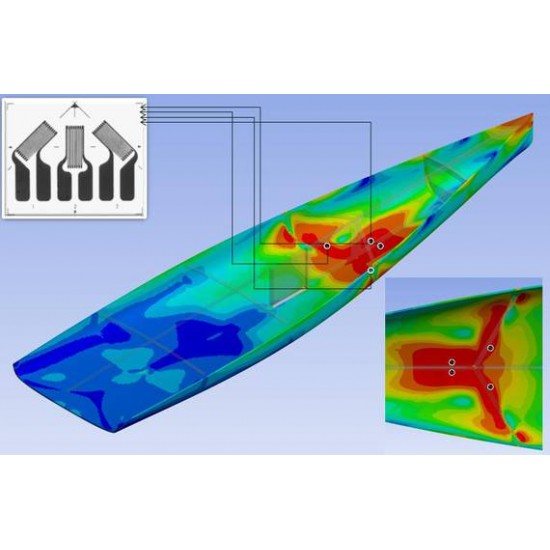

M series strain gauges are foil strain gauges for stress analysis of materials with high fatigue strength such as fiber composites. They can also be used in product development, for example in the aerospace or sporting goods industries.

In addition, M series strain gauges offer a very large temperature range. Due to their excellent fatigue life, M series strain gauges enable measurements to be repeated extremely frequently, also in case of high strain. Properties such as different geometries, resistance values, and measuring grid lengths can be combined to configure the ideal strain gauge—over 36 preferential strain gauges are available for immediate delivery.

- Temperature range: -200 to +300 °C

- Load cycles: Up to 10 million at +/- 2000 µm/m fatigue loading

- Measuring grid lengths: 1.5 to 6 millimeters

Read more

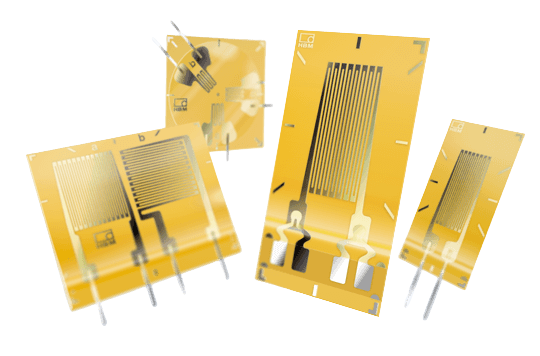

The C Series strain gauges are the ideal choice for structural tests at exceptional temperature conditions. They have an enormous temperature range and measure precisely even at very low temperatures down to -269 ° C. For a good mechanical flexibility, as well as flexibility and optimum adaptation to the material to be measured, the measuring grid of the C Series consists of a chrome-nickel special alloy on a polyimide foil.

Strain gauges of the C Series have an extremely wide temperature range at a very good price-performance ratio. The strain gauges of the C Series are available with three different geometries and are used, for example, in research and development, in the automotive industry, as well as in power plants and superconductors.

- Temperature range: -269 to +250 ° C

- Resistance: 120 and 350 Ohm

- Measuring grid lengths: 1.5 to 10 mm

HBK offer you strain gauges (SGs) in various geometries and sizes, available with temperature responses adapted to the following materials:

- Ferritic steel (10.8 ppm/K; 6.0 ppm/°F); temperature matching codes: 1

- Aluminum (23 ppm/K; 12.8 ppm/°F); temperature matching codes: 3

Read more

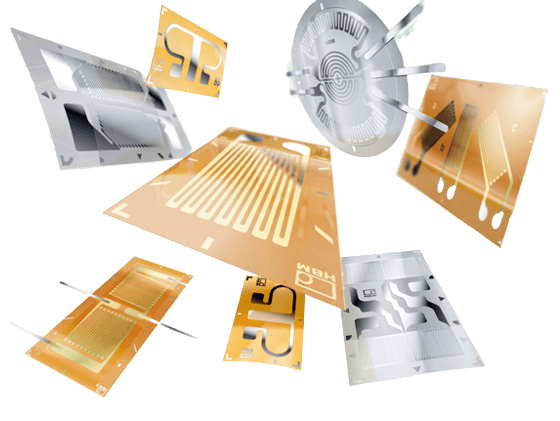

Regardless of whether the sensors you manufacture measure weight, force, torque, pressure, or another quantity, HBM offers you the strain gauge that best meets your needs. Benefit from over 50 years of experience, standard products that are available in large quantities from stock, a committed and accessible team of experts, and our excellent customer service.

Alongside two standard and two special series of high-grade strain gauges, further useful options such as pre-tinned solder tabs or strain gauges pre-coated with adhesive are available. In addition, we offer everything you need to build top-class transducers – from the adhesive to the balancing resistor. If you have any special requirements and/or need of low- or high-volume custom sensors, you can also collaborate with a dedicated team of design engineers to develop a custom solution.

Read more

Strain Gauges for Special Applications

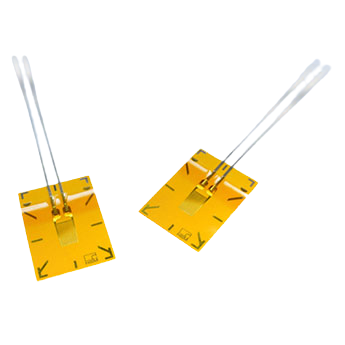

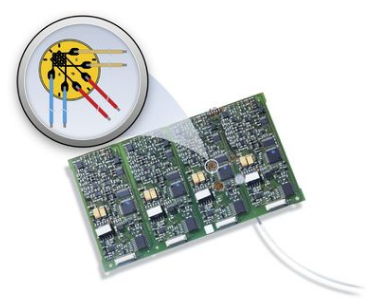

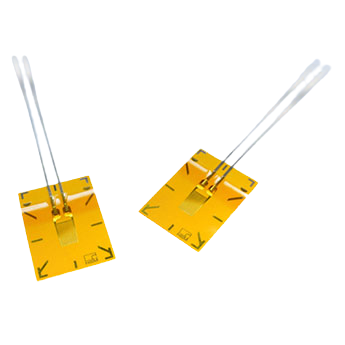

RF9 Strain Gauge Rosette for Printed Circuit Board Testing and Small Surfaces

Thanks to its three stacked measuring grids, the smallest version of the RF9 miniature SG rosette is only 5 mm in size. It enables biaxial stress states with unknown principal stress directions to be determined in the most confined of spaces, owing to its small diameter. The SG rosette is, therefore, particularly suitable for measurements on electric circuit boards or especially small components.

The following variants are available:

- Pre-wired with thin, enameled copper wires (d=0.2 mm) and a particularly small measuring grid: 1-RF9x-0.8/120ZE

- Pre-wired with thin, enameled copper wires and a 1 mm² measuring grid (JEDEC/IPC 9704-compliant): 1-RF9x-1/120ZE

- Pre-wired with 0.5 m enameled copper wires + 3 m temperature-resistant TPE cable (4-wire configuration), and a 2 mm² measuring grid (new and JEDEC/IPC 9704-compliant):1-RF9x-1.4/350ZE

- Without a cable: 1-RF95-0.8/120_W

Read more

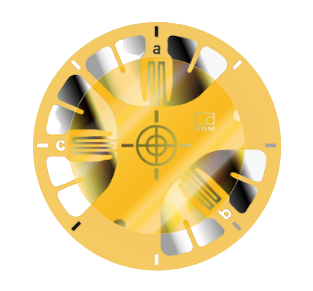

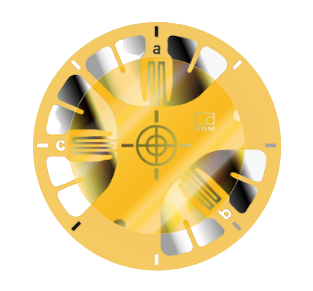

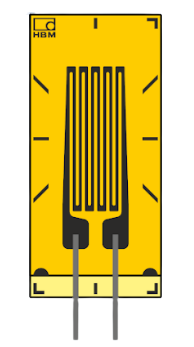

RY: Strain Gauges for Residual Stress Analysis (Ideal for Hole Drilling Method)

Determining residual stresses in materials (e.g. during casting, welding and forming processes) becomes easy with HBM's special strain gauges. These special strain gauges for residual stress analysis are available for precise and safe high-speed drilling (in combination with the MTS3000 drilling device from our partner company Sint Technology). For high-speed drilling, we also offer our patented six-wire strain gauges, which can compensate for non-centric boreholes, providing increased measurement accuracy.

- Supported residual stress measurement methods: integral hole-drilling, high-speed drilling

- Nominal resistance: 120 Ohm

- Measuring grid lengths: 1.5 to 5 mm

Read more

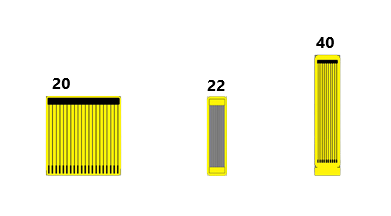

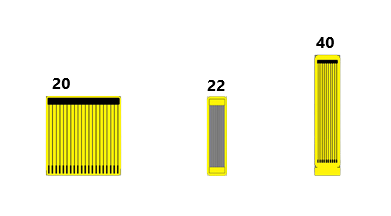

RDS: Strain Gauges For Determining Crack Propagation

The RDS strain gauges are used to determine crack propagation in a component. HBM offers four different types:

- RDS20 and RDS40 consist of electrically isolated conductor tracks (resistors), i.e. as the crack extends, individual circuits will be interrupted. If the circuits are contacted individually, the direction in which the gap is extending can be detected. In this case, individual circuits are interrupted as the crack propagates.

- RDS17.8 and RDS22 consist of conductor tracks connected in parallel which will tear if the crack extends under the crack propagation gauge. This will gradually increase the electrical resistance of the strain gauge as the crack continues to extend.

This change in resistance can be measured using a resistance meter or strain gauge amplifier.

Read more

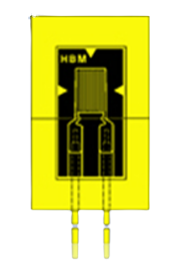

TT-3/100: Sensor for Measuring Temperature

The TT-3/100 strain gauge can be used to measure temperature. It has the appearance of a conventional metal strain gauge and is installed in the same easy and flexible way; however, it can also be installed on curved surfaces. Another plus of the TT-3/100 is its short response time to temperature variations. Processing of TT-3/100 temperature data requires a measurement instrument, for example, a measuring amplifier that enables resistors to be recorded as well.

Read more

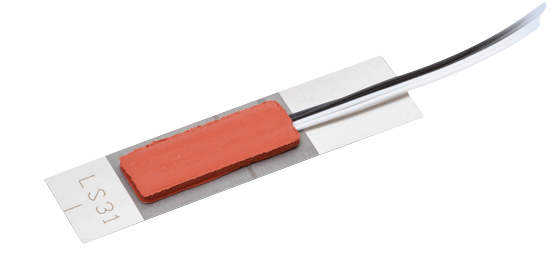

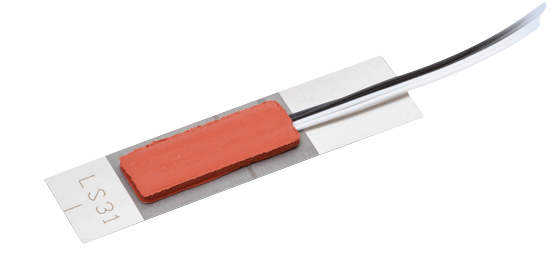

LS31HT: Weldable Strain Gauge for Rough Environments and High Temperatures

The LS31HT is a weldable strain gauge to be spot welded to steel structures and materials. It is ideal to be used "on site", when the cleanliness required for gluing cannot be guaranteed, for example on construction sites or in production plants, withstanding hazardous conditions. Such conditions would likely damage the adhesive bond of conventional strain gauges. The LS31 strain gauge is mounted by a simple spot welding process that requires little practice. It is fitted with 0.5-m stranded connection wires.

Typical applications for LS31HT include the mechanical load analysis on bridges, piles, tunnels, buildings, pipelines, wind power plants, and tanks.

We recommend using the VBS Fügetechnik c33 spot welder to install weldable strain gauges.

Read more

LE11: Strain Gauge for Moist and Chemical Environments

The LE11 is an encapsulated strain gauge with an IP67 degree of protection (in compliance with the chemical resistance of the adhesives). A 1-meter-long stranded connection wire with fluoropolymer insulation is included in the scope of supply. The LE11 strain gauge is encapsulated in a special plastic material and is, therefore, moisture proof and resistant against chemicals (with the exception of highly concentrated acids such as sulfuric or nitric acid). The LE11 comes with a 2-wire or 4-wire connection. The nominal (rated) resistance is 350 ohms and the temperature response is adapted for steel.

Read more

LD20: Strain Gauge for High Strain or Compression up to 10 %

The use of the strain gauge LD20 is recommended wherever an extremely high strain or compression can occur (>5 %). The LD20 has a maximum elongation of +/- 100,000 µm/m (+/-10 %) and is attached with 30 mm leads.

Note: In terms of fatigue life, the LD20 exhibits a lower resistance to alternating loads than standard Y series strain gauges.

Read more

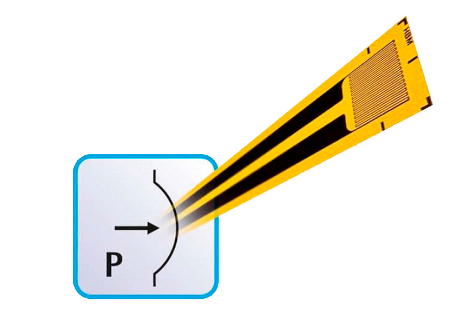

PMS40: Strain Gauge for Highly Dynamic Pressure Peaks

With transient pressure measurements, e.g. explosions, shock waves or ultrasonic applications, the rise time of the pressure curve is very short and the pressure peaks are high.

The PMS40 pressure measurement strain gauge enables high pressure peaks up to 10 kbar to be captured.

Read more

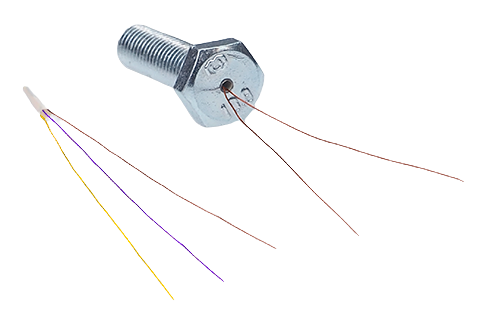

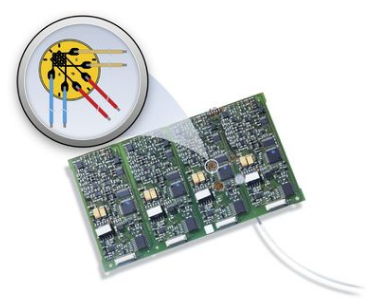

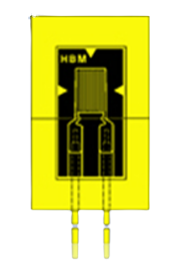

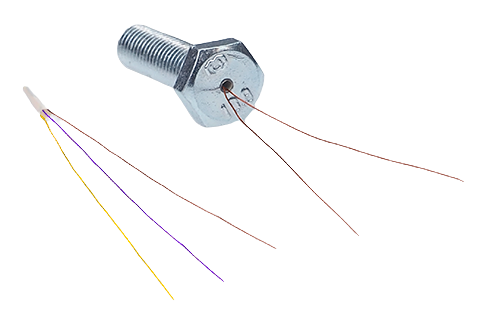

LB11 & TB21: Strain Gauges for Measurements in Screws and Bolts

Bolts are a common construction element used to connect various components. The LB11 and TB21 series of cylindric strain gauges with lead wires, have especially been designed to measure strain, force, and vibration in bolts, screws, and other axial construction elements.

They have been equipped with copper leads and can be used directly in pre-drilled bolt elements.For this, a 2 mm drilling in the structure is required. Both, LB11 and TB21, come as a tubular strain. gauge that can be used in a temperature range of –200°C to +140° C.

- The LB11 has a linear measuring grid in the strain direction. It is suitable for quarter-bridge applications and has a resistance of 120 Ω.

- The TB21 has two measuring grids arranged at 90° and is connected as a half-bridge. This allows for an improved temperature compensation at varying temperatures. The temperature compensation at +-5 °K temperature change causes a drift in the range of 0 to 80 µm/m, depending on the screw and the installation. This is due to the geometry of the application and differs significantly from installations on planar objects. The resistance of the strain gauge is 1000 Ω (+/- 1%).

Read more

Request Customized Strain Gauges Here

You have not found the right strain gauge for your application in our wide range of standard products? Then let us develop a customized strain gauge design for you! Please use the following form to describe your requirements as precisely as possible. Our team of experts will review your request with regard to feasibility and cost-effectiveness for you and HBM.

Read more

Strain Gauge Accessories

The quality of a measuring point is not only dependent on the strain gauge itself but also on the type of application and its implementation.

A perfectly functioning measuring point requires a thorough preparation of the application surface, careful bonding, correct connection, and a protective coating, With its strain gauge accessories, the HBM product range offers everything necessary for a good strain gauge application.

Read more